e-mail: sikandarmachines@gmail.com

175-176,New Gokal Ka Bagh, Adjoining Street Spring Field School,

100 Feet Road,East Mohan Nagar, Amritsar-143006 (Punjab) INDIA

Because there are no slots to provide slip in knife carrier cast iron part of machine.Direct holes ensures total grip of knife while making a cut.

NO SLIP OF CLUTCH & NO SOUND OF GEARS : NO SLIP OF CLUTCH & NO SOUND OF GEARS :Electro Magnetic Clutch ensures total Grip of power from motor to the cutting stock of any paper or boards,no sound of Gears due to oil dipped bronze gear box for noiseless running for long life of machine.

CORRECT PILE HEIGHT & LABEL CUTTING ARRANGEMENT :Semi Automatic Paper Cutting Machine India & Fully Automatic Paper Cutting Machines ensured.

SAFETY IN OPERATION :Safety is achieved by two handed cutting cycle switch,photo electric safety guard and A.C.fail safe brake.

OPERATION :The machine is operated all throgh ELECTRIC PUSH BUTTONS & transmission of power is through Electro-Magnetic Clutch and brake system.

TWO HANDED CUTTING CYCLE SWITCH :To make cut, you must press both cutting buttons simultaneously till the knife starts. If either one is released or both is released the machine stops immediately.

PHOTO ELECTRIC SAFETY GUARD :The photo electric transmitter receiver sensors are used for safety measures . If anything obstructs the infra red beams, the knife stops immediately. The positive drive of the machine ensures that when the knife is moving up after cutting the stock it stops only at its desired position.

CUTTING LINE CHECK :Cutting line check by foot padel.

MOTORISED BACK GAUGE :Motorised back gauge is inbuilt for this semi automatic paper cutter.

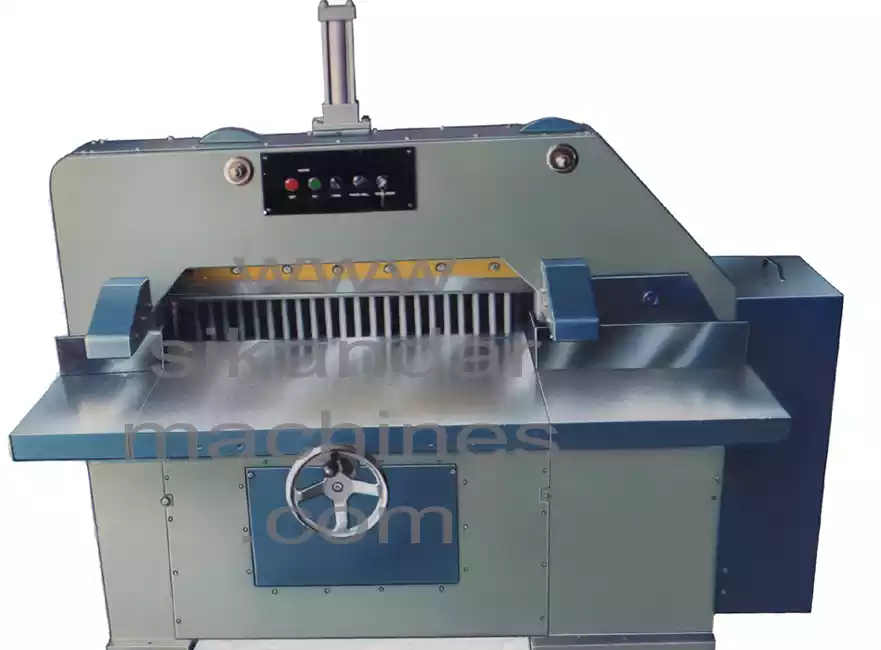

GENERAL DESCRIPTION :The cast iron frame has been reinforced for extra strength. It's sturdy.design eliminates all risks of vibration & excessive strain.

The smooth cutting cycle is fast & accurate, even when you're cutting hard material or high stock.

The fast cutting stroke is very accurate, to the knife carrier guides. All sliding surfaces have been precisely ground, guarantee of dependable precision & long service life.

The back gauge which moves smoothly is guided precisely on a coloumn & side plates length up to knife carrier ensures a right angle cut even at the smaller length of the stock. The hand wheel mechanism provides comfort to the operator for the fine edjustments of the cutting marks,when working in manual mode of programe.

Simple & safe knife change, knife guides provided with the machine, helps removing of the knife easily avoiding any danger to the operator & provision of hand switch locks the mains motor running while process is carried out, avoiding any chances of accidents.

| STANDARD EQUIPMENT | OPTIONAL EQUIPMENT | ||

| * Two knives | * Electronic Digital Read Out Scale | ||

| * Two side stock tables | * Photo Electric Safety Device | ||

| * Two front table side plates | * Detachable clamp plate | ||

| * Two rear table side plates | |||

| * Motor with electrical equipment for AC | |||

| * Two-handed trigger for cutting cycle | |||

| * Knife changing kit | |||

| * Complete set of tools | |||

| * Operators manual | |||

| TECHNICAL SPECIFICATION | |||

| DESCRIPTION | Model | Economic 85 | Economic 109 |

| Cutting Width | mm | 850 | 1090 |

| Cutting Length | mm | 850 | 1090 |

| Pile Height | mm | 125 | 125 |

| Cutting Speed | rpm | 36 | 36 |

| Front Table Depth | mm | 590 | 590 |

| Power Consumption | H.P. | 3.5 | 3.5 |

| Gross Weight | kg | 2000 | 2300 |